Integrated QEHS Management: Why One Stop Solutions beat Fragmented

Integrated QEHS Management: Why One-Stop Solutions Beat Fragmented Approaches

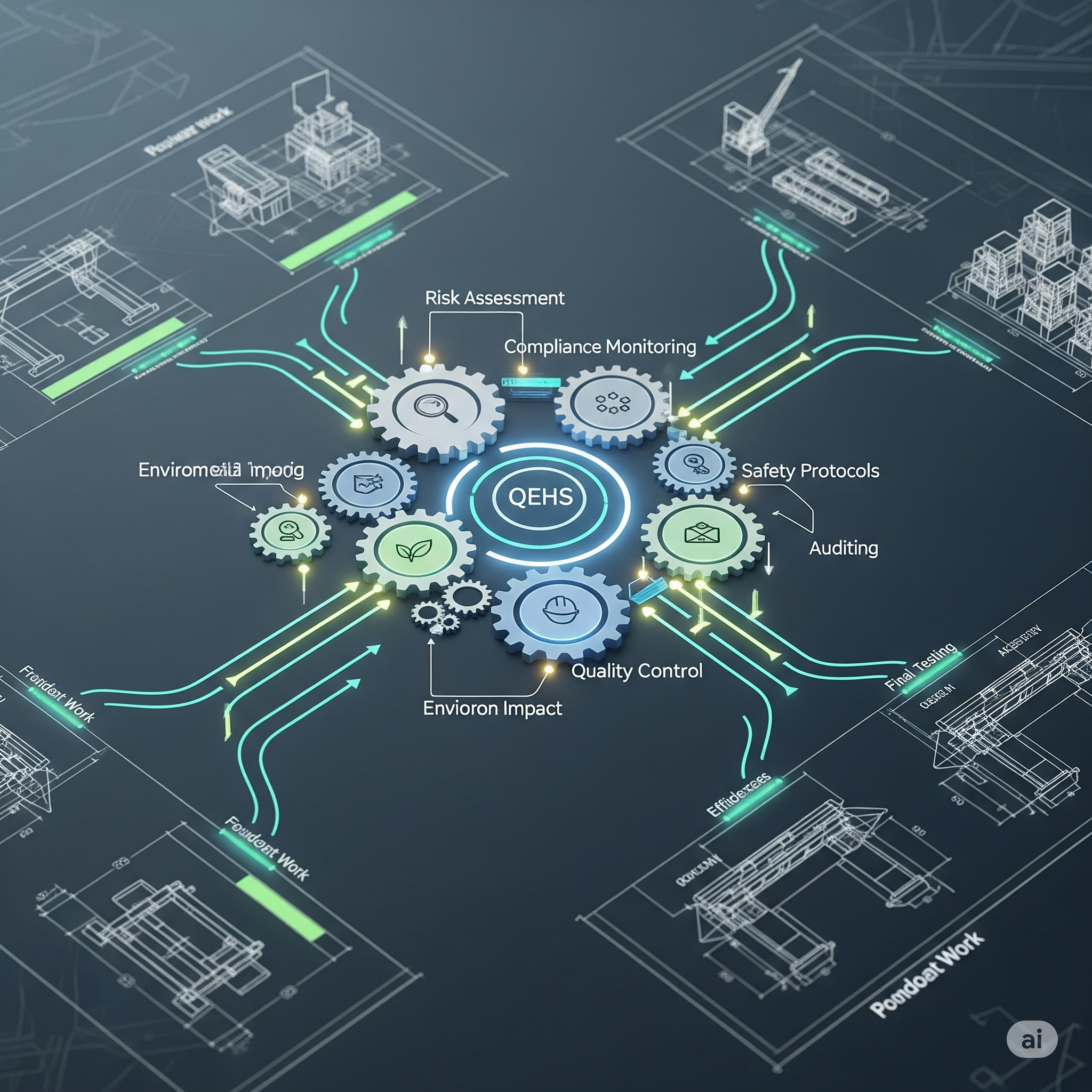

The complexity of modern infrastructure projects demands a fundamental shift in how organisations approach Quality, Environmental, Health, and Safety (QEHS) management. Whilst traditional project delivery often compartmentalises these critical functions across multiple specialists, leading organisations are discovering that integrated approaches deliver superior outcomes at reduced cost and complexity.

Following AuditCo’s recent strategic partnership with ASafe Global, we have observed firsthand how fragmented QEHS delivery creates unnecessary friction, increases project risk, and ultimately compromises both safety and commercial objectives. This analysis examines why integrated solutions consistently outperform fragmented approaches across critical infrastructure sectors.

The Cost of Fragmentation

Traditional project delivery typically involves separate contractors for environmental compliance, safety management, quality assurance, and audit functions. Each specialist operates within their domain, often with limited visibility of interconnected risks and dependencies. This fragmentation creates several systemic problems that compound throughout project lifecycles.

Communication Breakdowns

When QEHS functions operate in isolation, critical information frequently fails to reach the appropriate stakeholders. Environmental constraints identified during site assessment may not inform safety planning. Quality issues discovered during construction may not trigger appropriate environmental reviews. These communication gaps create blind spots that expose projects to regulatory non-compliance and operational failures.

Consider a recent data centre project where environmental specialists identified groundwater concerns during site preparation, but this information never reached the construction safety team. When foundation work began, unexpected water ingress created both safety hazards and environmental compliance issues that could have been prevented through integrated planning.

Duplicated Efforts and Wasted Resources

Fragmented approaches inevitably lead to duplicated documentation, overlapping inspections, and redundant reporting requirements. Multiple contractors conducting separate site assessments waste both time and money whilst potentially disrupting ongoing activities. Administrative overhead multiplies as project managers coordinate between disparate teams with different reporting cycles, documentation standards, and communication protocols.

Our analysis of infrastructure projects reveals that fragmented QEHS delivery typically increases administrative burden by 30-40% compared to integrated approaches. This overhead represents pure waste that adds no value to project outcomes whilst consuming resources that could be better deployed on value-adding activities.

Inconsistent Standards and Methodologies

When different organisations handle various QEHS functions, inconsistencies in standards, methodologies, and reporting inevitably emerge. Environmental assessments may use different risk classification systems than safety evaluations. Quality control procedures may operate on different sampling frequencies than compliance audits. These inconsistencies create confusion, complicate decision-making, and increase the likelihood of gaps or oversights.

Delayed Response to Emerging Issues

Fragmented systems struggle to respond rapidly to emerging issues that span multiple QEHS domains. When problems arise that involve environmental, safety, and quality considerations, resolution requires coordination between multiple parties, each with their own priorities, schedules, and decision-making processes. This complexity inevitably slows response times, potentially allowing minor issues to escalate into major problems.

The Integrated Advantage

Integrated QEHS management addresses these systemic weaknesses by unifying responsibility, standardising approaches, and ensuring seamless coordination across all compliance and safety functions. The benefits extend far beyond simple efficiency gains.

Single Point of Accountability

Integrated solutions establish clear accountability for all QEHS outcomes under unified management. This eliminates finger-pointing when issues arise and ensures consistent application of standards across all project phases. Project directors benefit from simplified oversight, with one team responsible for all compliance and safety outcomes rather than managing relationships with multiple specialists.

This unified accountability proves particularly valuable during regulatory inspections or incident investigations, where consistent documentation and clear responsibility lines facilitate rapid resolution. Regulatory bodies appreciate dealing with organisations that demonstrate integrated management systems rather than fragmented arrangements that complicate oversight activities.

Holistic Risk Assessment

Integrated teams can identify and address interconnected risks that fragmented approaches often miss. Environmental factors that influence safety planning, quality requirements that affect environmental compliance, and health considerations that impact both environmental and safety protocols can be evaluated comprehensively rather than in isolation.

For example, ASafe Global’s integrated approach recently identified how proposed changes to cooling water systems in a data centre would affect both environmental discharge requirements and workplace safety protocols. This holistic assessment enabled design modifications that addressed both concerns proactively, avoiding costly retrofits and potential compliance violations.

Streamlined Documentation and Reporting

Unified management systems eliminate duplicated documentation whilst ensuring comprehensive coverage of all regulatory requirements. Integrated teams maintain single master documents that address multiple compliance frameworks simultaneously, reducing administrative burden whilst improving accuracy and consistency.

This streamlined approach proves particularly valuable for organisations operating across multiple jurisdictions with different regulatory requirements. Integrated systems can accommodate varying local requirements within unified frameworks, ensuring compliance whilst minimising administrative complexity.

Accelerated Decision-Making

When all QEHS functions operate under unified management, decisions can be made rapidly without requiring coordination between multiple organisations. Issues that span multiple domains can be assessed and resolved by teams with comprehensive understanding of all relevant factors, eliminating delays associated with inter-organisational coordination.

This acceleration proves crucial during construction phases when rapid decisions are required to maintain project schedules. Integrated teams can assess quality, environmental, and safety implications simultaneously, enabling immediate resolution rather than sequential evaluation by separate specialists.

Real-World Applications

The theoretical advantages of integrated QEHS management translate into measurable improvements across various infrastructure sectors. Our experience across digital infrastructure, oil and gas, and industrial manufacturing demonstrates consistent patterns of enhanced performance.

Digital Infrastructure Projects

Data centre and fibre network projects face particularly complex QEHS requirements due to their intersection of construction, technology, and operational considerations. Environmental compliance during construction must align with ongoing operational requirements. Safety protocols must accommodate both construction activities and sensitive electronic equipment. Quality assurance must address both physical construction and technical performance parameters.

Integrated management ensures these considerations are balanced appropriately throughout project delivery. Recent projects have demonstrated 25% reduction in compliance-related delays when integrated teams manage all QEHS functions compared to fragmented approaches. This improvement stems from proactive identification of potential conflicts and early resolution of interdisciplinary issues.

Oil and Gas Operations

Process industries face stringent regulatory requirements across environmental protection, workplace safety, and operational quality. Traditional approaches often struggle to balance these competing demands, particularly when different specialists prioritise their individual domains without considering broader implications.

Integrated QEHS management enables process industries to optimise across all compliance domains simultaneously. Safety procedures are designed to support environmental protection goals. Quality systems incorporate both safety and environmental considerations. Environmental management systems address workplace health alongside ecological protection.

Industrial Manufacturing

Manufacturing facilities must integrate QEHS management across design, construction, commissioning, and ongoing operations. Each phase presents different risk profiles and regulatory requirements, but decisions made during early phases affect compliance throughout facility lifecycles.

Integrated approaches ensure that design decisions consider long-term operational compliance requirements. Construction methodologies support both safety and environmental goals. Commissioning procedures validate quality, safety, and environmental performance simultaneously. This lifecycle perspective prevents costly retrofits and compliance issues that often emerge when QEHS functions are managed separately.

Implementation Considerations

Successful integrated QEHS management requires careful attention to several critical factors that distinguish effective implementations from superficial consolidation efforts.

Cultural Integration

Bringing together previously separate QEHS functions requires more than organisational restructuring. Teams must develop shared understanding of interdisciplinary risks and collaborative approaches to problem-solving. This cultural integration takes time and requires deliberate effort to break down traditional silos.

Effective integrated teams develop cross-functional expertise that enables environmental specialists to understand safety implications, safety professionals to appreciate quality requirements, and quality experts to recognise environmental considerations. This cross-pollination of knowledge enhances overall team capability whilst maintaining specialised expertise where required.

Technology Platform Integration

Integrated QEHS management depends on technology platforms that support unified data collection, analysis, and reporting across all compliance domains. Fragmented systems that require separate data entry and reporting for different functions undermine integration benefits and create additional administrative burden.

Modern integrated platforms enable single-point data entry that automatically populates multiple compliance frameworks, generates unified reports that address various regulatory requirements, and provide dashboards that present integrated risk assessments across all QEHS domains.

Regulatory Coordination

Different regulatory bodies often have varying expectations regarding QEHS management approaches. Integrated systems must accommodate these differences whilst maintaining unified internal processes. This requires careful mapping of regulatory requirements and design of systems that satisfy multiple regulatory frameworks without unnecessary duplication.

Successful implementations engage with regulatory bodies early to explain integrated approaches and demonstrate how unified systems meet or exceed traditional compliance expectations. This proactive engagement prevents misunderstandings and ensures regulatory acceptance of integrated methodologies.

Measuring Success

Integrated QEHS management delivers measurable improvements across multiple performance dimensions. Organisations implementing integrated approaches typically observe significant improvements in key performance indicators within 12-18 months of implementation.

Efficiency Metrics

Administrative efficiency improves substantially under integrated management. Document preparation time typically reduces by 35-45% as unified systems eliminate duplicated efforts. Inspection and audit activities become more efficient as integrated teams can address multiple compliance domains simultaneously rather than requiring separate visits by different specialists.

Communication efficiency also improves markedly. Internal coordination time decreases as unified teams eliminate inter-organisational coordination requirements. External stakeholder management becomes more efficient as clients and regulatory bodies deal with single points of contact rather than multiple specialists.

Quality Outcomes

Integrated approaches consistently deliver superior quality outcomes compared to fragmented alternatives. Comprehensive risk assessments identify potential issues earlier in project lifecycles when resolution costs are lower. Coordinated response to emerging issues prevents minor problems from escalating into major failures.

Client satisfaction improves as integrated teams provide more consistent service delivery and clearer accountability. Regulatory compliance improves as unified systems ensure comprehensive coverage without gaps or overlaps that characterise fragmented approaches.

Cost Performance

Total cost of ownership for QEHS services typically reduces by 20-30% under integrated management despite potentially higher individual service costs. These savings stem from eliminated duplication, improved efficiency, and reduced risk of costly compliance failures or safety incidents.

Risk mitigation provides additional financial benefits through reduced insurance premiums, fewer regulatory penalties, and decreased likelihood of project delays due to compliance issues. These indirect savings often exceed direct cost reductions, providing compelling financial justification for integrated approaches.

Future Considerations

The trend towards integrated QEHS management reflects broader industry evolution towards more sophisticated, holistic approaches to complex project delivery. As regulatory requirements continue to increase in complexity and interdisciplinary risks become more prevalent, integrated approaches will become increasingly essential rather than merely advantageous.

Organisations that embrace integrated QEHS management position themselves to capitalise on emerging opportunities whilst competitors struggle with increasingly unwieldy fragmented approaches. The learning curve associated with integration implementation provides competitive advantages that compound over time as teams develop enhanced capabilities and refined processes.

The partnership between AuditCo and ASafe Global exemplifies this evolution, combining audit and inspection expertise with comprehensive QEHS management capabilities to deliver integrated solutions that address the full spectrum of client requirements. This collaboration demonstrates how industry leaders are responding to market demands for more sophisticated, comprehensive approaches to complex compliance challenges.

Integrated QEHS management represents more than operational efficiency improvement. It reflects fundamental recognition that modern infrastructure projects require holistic approaches that address interconnected risks comprehensively rather than managing individual components in isolation. Organisations that embrace this reality will establish competitive advantages that prove increasingly valuable as project complexity continues to increase.

For More Information Visit https://asafeglobal.com/ or contact info@auditco.co.uk

www.auditco.co.uk