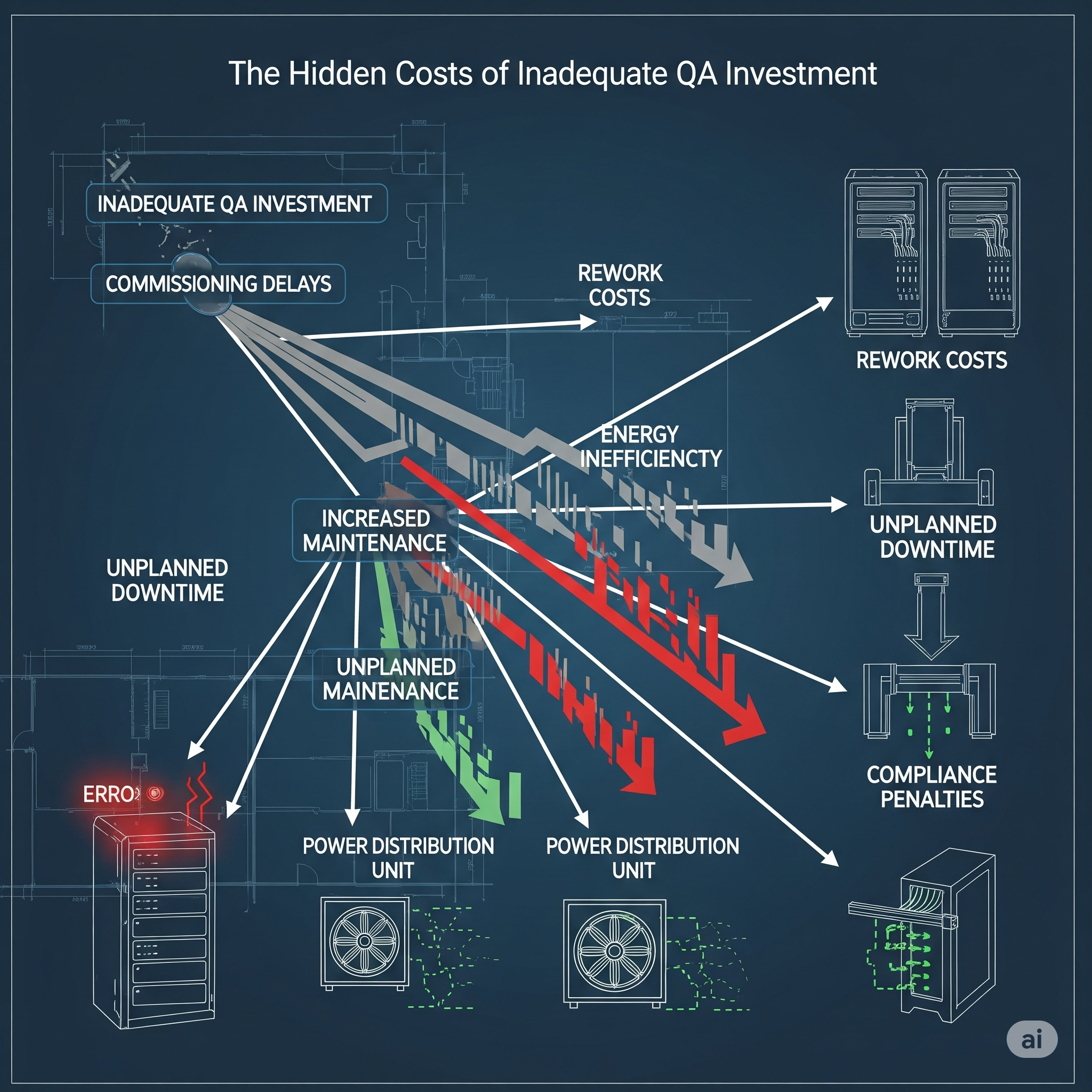

The Hidden Costs of Poor Construction Quality Assurance in Data Center Projects

The Hidden Costs of Poor Construction Quality Assurance in Data Center Projects

Data centre construction represents one of the most technically demanding and financially critical infrastructure sectors, where quality failures can result in catastrophic operational consequences and enormous financial losses. Yet despite stakes that can reach hundreds of millions of pounds, many organisations continue to underestimate the true cost of inadequate construction quality assurance, focusing primarily on immediate construction expenses whilst overlooking the far more significant long-term operational and risk implications.

Our analysis of data centre projects across EMEA and APAC markets reveals that poor construction quality assurance typically costs organisations 3-5 times more than comprehensive quality programmes, when total lifecycle costs are properly calculated. These hidden expenses manifest across multiple dimensions throughout facility lifecycles, creating financial burdens that often exceed original construction budgets.

Understanding the True Cost Structure

Traditional cost analysis focuses narrowly on construction expenditure, treating quality assurance as an additional expense rather than recognising its role in preventing far more significant downstream costs. This perspective fundamentally misrepresents the economic equation, leading to decisions that optimise short-term construction costs whilst creating enormous long-term liabilities.

Direct Construction Cost Misconceptions

Many project directors view quality assurance as non-essential overhead that increases construction costs without delivering tangible value. This perspective emerges from focus on immediate, visible expenses rather than understanding quality assurance as insurance against future failures. When construction budgets face pressure, quality programmes often become targets for reduction despite their critical role in preventing far costlier problems.

Comprehensive construction quality assurance typically represents 2-4% of total construction costs for data centre projects. However, the cost of remedying quality failures after construction completion often exceeds 15-25% of original construction value, creating a risk-reward ratio that strongly favours investment in preventive quality measures.

Operational Impact Multipliers

Data centres operate in environments where minor quality failures can cascade into major operational disruptions. Unlike conventional buildings where quality issues primarily affect comfort or aesthetics, data centre quality problems directly impact critical infrastructure that supports substantial revenue streams for client organisations.

A recent case study involving a hyperscale data centre in Frankfurt illustrates this multiplier effect. Poor quality assurance during cooling system installation resulted in uneven thermal distribution that wasn’t identified until commissioning. Remediation required partial facility shutdown during peak demand periods, resulting in lost revenue that exceeded £2.3 million over the correction period, compared to construction quality assurance costs that would have totalled approximately £180,000.

Risk Amplification Through Interconnected Systems

Data centre infrastructure involves numerous interconnected systems where quality failures in one component can compromise performance across multiple domains. Power distribution problems can affect cooling efficiency. Structural deficiencies can impact cable management. Environmental control failures can compromise both equipment reliability and energy efficiency.

These interconnections mean that quality failures rarely remain isolated, instead propagating through facility systems in ways that compound both immediate remediation costs and long-term operational consequences. Traditional cost models fail to capture these amplification effects, significantly underestimating the true financial risk of poor construction quality assurance.

Immediate Financial Consequences

Quality failures in data centre construction create immediate financial impacts that often become apparent during commissioning or early operational phases. These costs are typically visible and measurable, making them easier to quantify than longer-term consequences, yet they still frequently exceed original quality assurance investments by substantial margins.

Commissioning Delays and Cost Overruns

Poor construction quality inevitably extends commissioning periods as teams identify and remedy deficiencies that should have been prevented during construction. These delays create direct costs through extended consultant engagement, additional testing requirements, and prolonged construction site overhead. More significantly, commissioning delays often postpone revenue generation for facilities designed to support immediate operational requirements.

Our experience with data centre projects demonstrates that quality-related commissioning delays average 6-12 weeks beyond planned schedules. For facilities designed to generate £1-3 million monthly revenue, these delays create immediate financial impacts that dwarf construction quality assurance costs whilst creating operational disruption for client organisations.

Rework and Remediation Expenses

Quality failures discovered during commissioning or early operations require immediate remediation that typically costs 3-7 times more than proper initial construction. Rework often requires dismantling completed installations, sourcing replacement materials on expedited schedules, and coordinating remediation activities around operational constraints.

Recent projects have demonstrated rework costs exceeding £500,000 for electrical distribution problems that could have been prevented through quality assurance programmes costing less than £75,000. These ratios are typical across data centre construction, where technical complexity amplifies both the likelihood and consequences of quality failures.

Performance Testing and Validation Costs

Facilities with quality-related performance issues require extensive additional testing and validation to demonstrate compliance with operational requirements. This testing often involves expensive specialised equipment, extended consultant engagement, and repeated validation cycles as problems are identified and addressed.

Beyond direct testing costs, performance validation delays often require temporary operational workarounds that create additional expenses through redundant equipment rental, alternative facility arrangements, or operational constraints that reduce facility efficiency and revenue potential.

Long-Term Operational Impacts

The most significant costs of poor construction quality assurance manifest during facility operations, where quality-related problems create ongoing inefficiencies, increased maintenance requirements, and elevated risk of catastrophic failures. These costs accumulate over facility lifecycles, often exceeding original construction costs whilst creating persistent operational challenges.

Energy Efficiency Degradation

Construction quality problems frequently compromise energy efficiency through poor insulation, inadequate sealing, misaligned equipment, and suboptimal system integration. In data centres where energy represents 60-70% of ongoing operational costs, efficiency degradation creates substantial financial impacts that compound annually throughout facility lifecycles.

Analysis of operational data centres reveals that construction quality issues typically reduce energy efficiency by 8-15% compared to properly constructed facilities. For large data centres consuming 20-50 MW, this degradation represents annual energy cost increases of £1.2-4.5 million, creating lifecycle costs that can exceed £50-150 million over typical 15-20 year operational periods.

Accelerated Equipment Degradation

Poor construction quality creates operational environments that accelerate equipment degradation through temperature variations, vibration transmission, contamination exposure, and power quality problems. This acceleration reduces equipment lifecycles whilst increasing maintenance requirements and failure rates.

Equipment replacement costs in data centres can range from £10-50 million for major upgrades, making construction quality that extends equipment lifecycles extremely valuable. Quality problems that reduce equipment life by even 2-3 years create substantial financial impacts through premature replacement requirements and lost operational efficiency during equipment lifecycle transitions.

Maintenance Cost Escalation

Facilities with construction quality problems require substantially higher maintenance expenditure to achieve equivalent operational reliability. Poor workmanship creates ongoing maintenance challenges through inadequate access provisions, substandard material installations, and system configurations that complicate routine maintenance activities.

Our analysis indicates that maintenance costs for data centres with construction quality issues typically exceed well-constructed facilities by 35-60% annually. Over facility lifecycles, these additional maintenance costs often total £5-15 million beyond normal maintenance expenditure, representing pure waste that could have been prevented through proper construction quality assurance.

Risk and Reliability Consequences

Beyond quantifiable operational costs, poor construction quality assurance creates elevated risks of catastrophic failures that can result in enormous financial losses, regulatory penalties, and reputational damage. These risks represent perhaps the most significant hidden costs of inadequate quality programmes, as their potential impact far exceeds typical construction or operational expenses.

Unplanned Downtime Risk

Data centre downtime can cost client organisations £5,000-50,000 per minute depending on facility criticality and supported operations. Construction quality problems that increase downtime risk create enormous potential liabilities that dwarf construction quality assurance investments.

Recent industry analysis indicates that facilities with construction quality issues experience 40-60% higher rates of unplanned downtime compared to well-constructed alternatives. Even small increases in downtime probability create substantial expected value costs when multiplied by potential downtime expenses and facility lifecycles.

Regulatory Compliance Challenges

Poor construction quality can compromise regulatory compliance across environmental, safety, and operational domains. Compliance failures create direct costs through penalties and remediation requirements, whilst also creating indirect costs through operational restrictions and regulatory oversight intensification.

Environmental compliance failures in data centres can result in penalties exceeding £1 million whilst also creating operational constraints that reduce facility efficiency and capacity utilisation. Safety compliance problems can result in operational restrictions that compromise facility availability during critical demand periods.

Insurance and Liability Implications

Construction quality problems can void insurance coverage or result in premium increases that create substantial ongoing costs. Quality-related failures may also create liability exposure for organisations that cannot demonstrate appropriate due diligence in construction quality assurance.

Insurance premium increases following quality-related incidents can total hundreds of thousands of pounds annually, whilst liability exposure for business interruption claims can reach tens of millions of pounds for critical facility failures that affect client organisations.

Technology and Performance Impacts

Data centres house extremely sensitive equipment that requires precise environmental conditions and stable power delivery to operate reliably. Construction quality problems that compromise these requirements create both immediate performance issues and long-term reliability challenges that affect facility value propositions and client satisfaction.

Power Quality and Distribution Issues

Electrical installation quality directly affects power stability and reliability throughout data centres. Poor electrical workmanship can create harmonics, voltage variations, and distribution imbalances that compromise equipment performance whilst increasing failure rates and energy consumption.

Power quality problems often require expensive mitigation equipment and ongoing monitoring to maintain acceptable performance levels. These costs typically exceed £500,000-2 million for major facilities, whilst also creating ongoing operational constraints that reduce facility flexibility and efficiency.

Thermal Management Complications

Cooling system installation quality directly affects thermal management effectiveness and energy efficiency. Poor installation practices can create hot spots, airflow restrictions, and control system problems that compromise both equipment reliability and operational efficiency.

Thermal management problems often require facility modifications or operational constraints that reduce capacity utilisation whilst increasing energy consumption. These impacts can reduce facility revenue potential by 10-20% whilst also increasing operational costs through higher energy consumption and accelerated equipment degradation.

Structural and Seismic Performance

Structural quality affects both immediate safety and long-term facility resilience. In seismically active regions, structural deficiencies can compromise facility survival during seismic events, creating enormous potential losses through equipment damage and business interruption.

Structural remediation in operational data centres presents extreme challenges due to equipment sensitivity and operational requirements. Post-construction structural improvements often cost 5-10 times more than proper initial construction whilst creating substantial operational disruption during implementation.

Case Study Analysis

Our partnership with ASafe Global has provided extensive insight into quality assurance effectiveness across numerous data centre projects. These experiences demonstrate consistent patterns where comprehensive quality programmes deliver substantial financial benefits compared to fragmented or inadequate approaches.

European Hyperscale Facility

A recent 45 MW hyperscale facility in the Netherlands demonstrates the financial impact of comprehensive construction quality assurance. Initial quality programme investment totalled €2.1 million over the 18-month construction period, representing 2.8% of total construction costs.

Post-commissioning analysis revealed that comprehensive quality assurance prevented an estimated €18.5 million in potential remediation costs, commissioning delays, and early operational problems. Energy efficiency measurements confirmed performance within 1% of design specifications, avoiding ongoing operational cost increases that typically total €2-4 million annually for similar facilities with quality-related performance degradation.

Regional Colocation Facility

A 12 MW colocation facility in Frankfurt provides contrast between areas with comprehensive quality assurance and sections where quality programmes were reduced due to budget pressures. Areas with comprehensive quality assurance achieved commissioning on schedule with minimal rework requirements, whilst areas with reduced quality programmes experienced 8-week commissioning delays and €1.3 million in remediation costs.

Operational data collected over 24 months shows that areas with comprehensive construction quality assurance consume 12% less energy whilst demonstrating 35% fewer maintenance requirements compared to areas with reduced quality programmes. These operational differences create ongoing cost impacts that exceed original quality programme savings within 18 months of facility operation.

Manufacturing and Industrial Applications

Quality assurance principles developed for data centre applications translate effectively to other critical infrastructure sectors. A recent pharmaceutical manufacturing facility in Ireland utilised integrated quality assurance approaches that prevented construction delays whilst ensuring regulatory compliance across environmental, safety, and operational domains.

Comprehensive quality assurance investment of £180,000 prevented estimated remediation costs exceeding £2.4 million whilst ensuring regulatory approval schedules that enabled planned production commencement. Ongoing operational monitoring confirms performance specifications that support full production capacity without quality-related constraints.

Implementation Best Practices

Effective construction quality assurance requires systematic approaches that address quality throughout project lifecycles rather than treating quality as isolated inspection activities. Successful programmes integrate quality planning into project design whilst maintaining rigorous oversight throughout construction execution.

Early Integration and Planning

Quality assurance programmes must begin during design phases to ensure constructability, specification clarity, and quality verification methodologies. Early integration prevents design decisions that complicate construction quality whilst establishing clear quality standards and verification procedures.

Design phase quality planning typically requires 10-15% of total quality programme resources but delivers disproportionate value through prevention of quality issues that would be far more expensive to remedy during construction or operations.

Comprehensive Documentation and Traceability

Effective quality programmes maintain comprehensive documentation that enables quality verification, regulatory compliance demonstration, and ongoing operational support. Documentation standards must address both immediate construction requirements and long-term operational needs.

Digital documentation platforms increasingly enable real-time quality tracking, automated compliance reporting, and integrated quality management across multiple project stakeholders. These platforms reduce administrative burden whilst improving quality oversight effectiveness and audit trail completeness.

Integrated Stakeholder Coordination

Quality assurance effectiveness depends on coordination between designers, contractors, commissioners, and operational teams. Fragmented quality approaches that operate independently often miss critical integration points where quality failures can propagate across multiple systems.

Integrated quality programmes ensure consistent standards application, coordinated inspection activities, and unified resolution of quality issues that span multiple contractors or systems. This coordination reduces both quality programme costs and the likelihood of quality failures that emerge from poor stakeholder coordination.

Financial Justification and ROI Analysis

Comprehensive construction quality assurance delivers measurable returns on investment that justify programme costs across multiple financial metrics. These returns emerge through prevention of larger costs rather than direct revenue generation, requiring lifecycle analysis to capture full financial benefits.

Risk-Adjusted Cost Analysis

Proper financial analysis must include risk-adjusted costs that reflect both the probability and consequences of quality failures. Expected value calculations that combine failure probabilities with potential failure costs demonstrate that quality assurance investments typically deliver returns exceeding 400-800% over facility lifecycles.

Conservative risk analysis typically assumes quality failure probabilities of 15-25% for complex data centre systems without comprehensive quality assurance. Failure consequence costs often range from £2-15 million depending on failure types and facility criticality, creating expected values that substantially exceed quality programme investments.

Lifecycle Cost Optimisation

Quality assurance programmes that focus narrowly on construction costs often miss opportunities to optimise total lifecycle costs through quality improvements that deliver ongoing operational benefits. Comprehensive programmes consider both construction quality and operational performance optimisation to maximise total financial benefits.

Lifecycle cost analysis frequently demonstrates that quality programme investments deliver annual operational savings that exceed programme costs within 2-4 years of facility operation, creating positive cash flows throughout remaining facility lifecycles whilst also reducing operational risks and improving facility reliability.

The evidence is unambiguous: comprehensive construction quality assurance represents essential insurance against far more significant downstream costs whilst also delivering operational benefits that enhance facility performance and profitability. Organisations that recognise quality assurance as investment rather than expense position themselves for superior operational outcomes and financial performance throughout facility lifecycles.

Our experience through the AuditCo and ASafe Global partnership continues to demonstrate that integrated quality approaches deliver superior outcomes compared to fragmented alternatives, whilst also providing the comprehensive oversight that modern data centre projects require to achieve their operational and financial objectives.

For More Information Visit https://asafeglobal.com/ or contact info@auditco.co.uk

www.auditco.co.uk

The Hidden Costs of Poor Construction Quality Assurance in Data Center Projects

Related Posts

Data Centre Modernisation: Managing HVAC, Power, and Cooling System Upgrades

In the evolving business landscape, the significance of Environmental, Social, and Governance (ESG) principles is…

Risk Assessment Methodologies for Complex Industrial Manufacturing Projects

In the evolving business landscape, the significance of Environmental, Social, and Governance (ESG) principles is…

ISO 9001, 14001 and 45001: Integrated Management Systems for Modern Enterprises

In the evolving business landscape, the significance of Environmental, Social, and Governance (ESG) principles is…